Moisture Measurement – an Essential for Automating Concrete Production

The current worldwide health challenges are causing many organisations to adjust their working practices to minimise the staff involved in a site whilst still managing full production schedules.

Automation is one of the critical components in this, and one of the keys to full control of processes is the ability to measure and react to changes in the raw materials as quickly and accurately as possible.

One of the major sources of inconsistency in both Ready-Mix and Precast concrete production is the ever-varying moisture content of the sand and aggregates. Water content changes can originate from different parts of the concrete production process with differing effects:

- Natural moisture content variation in aggregates.

- Uncovered material transport or storage systems allow increments of water content by rainfall or their reduction by evaporation.

- Accuracy of the water and admixture dosing systems into the concrete mixer.

The most significant source of moisture variation is the natural aggregate moisture content. A variation of 1% moisture content in the dry aggregates by weight results in an error of 10 Kg of aggregate loaded into the mixer for every 1,000 Kg of dry aggregate weighed.

Obviously, the greater the variation of moisture and the greater the weight of aggregate used, the more serious this condition becomes and, as the water content in aggregates can be as high as 16%, this has large repercussions to the economics of trading in this material.

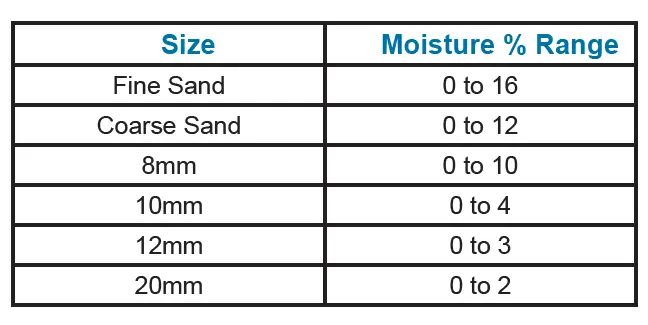

The table on the right shows the ranges of moisture that different size aggregates can ‘hold’ as free water and how the maximum increases with the fineness of the aggregate.

Many common mix designs have larger proportions of fine materials, so, for best results, concrete producers are best advised to concentrate on initially measuring moisture in the sand and coarse stone materials for the biggest return on investment.

Moisture Measurement Sensors for Concrete Production

Today, there are products available in the market that allow the measurement of the moisture content of aggregates and fresh concrete with a good degree of accuracy.

The microwave technique has emerged as the most suitable for the measurement of moisture in concrete production. Microwave technology is superior mainly due to its high accuracy (usually in the range of +-0.2% depending on the quality of the calibration), its lack of influence by dust or colour, and the competitive cost-benefit relationship of this type of equipment.

Measuring Moisture in Aggregate Bins

In Ready-Mix concrete, varying moisture content affects the yield achieved for a given amount of cement, the slump and the strength of the concrete produced.

A modern Ready-Mix plant typically has microwave moisture sensors installed at the gates of each of the aggregate bins.

Once the sensor has been set up correctly, average moisture readings can be taken in real-time during each batch and used by the control system to adjust the dosing targets of the aggregates. The sensor enables the system to ensure that the correct dry weight of each aggregate is loaded into the mixer.

At the end of the aggregate loading, the total water in the material can be calculated from the moistures recorded during the batching. This calculation is then used to also reduce the water added into the mixer to get the correct final water/cement ratio.

A plant producing 160m³/day of concrete would see a typical payback period for moisture measurement equipment of 3 months, gaining considerable benefits in both increased yield and improved quality.

High-quality materials and well-controlled moisture levels are critical for precast and concrete product manufacturers to ensure consistent products. Significant savings in cement, colour, and admixtures, including reductions in the number of wasted batches, are all common benefits of moisture measurement.

As well as installing aggregate bin moisture sensors at their plants to ensure aggregate dry weight batching, high quality precast and concrete product manufacturers often also use moisture control in the mixer to ensure the correct total water in the mix, batch after batch.

Measuring Moisture in Mixers

Measuring the moisture of fresh concrete in a mixer allows the concrete producer to have full control over the final moisture content before the mix is discharged. Measuring the moisture whilst mixing ensures that variations such as unmeasured aggregates, or environmental influences (rain or evaporation from heat) during transport from the hopper to the mixer, are eliminated.

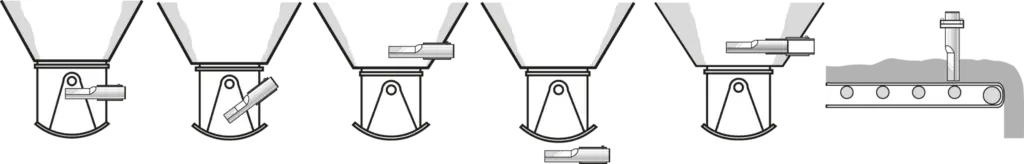

There are two options for moisture measurement in mixers. The first option is a flush-mounted sensor fitted to the floor of a pan mixer or the belly or end wall of a shaft mixer. The second option is an ‘in-mix’ sensor, which either mounts on the mixer scraper arm in a static pan mixer or is mounted statically in a rotating pan mixer. The version of the ‘in-mix’ sensor, the Hydro-Probe Orbiter, uses a fully ceramic sensing head unit to offer producers the fastest response available in the market.

The measurements from mixer floor moisture sensors and in-mix sensors are used to calculate the correct volume of water required to achieve constant water contents inside the mixer, batch after batch.

Homogeneity Control using Moisture Measurement

Using moisture as an indicator of the degree of homogeneity achieved by the concrete mixer at any mixing stage is also possible using microwave mixer sensors.

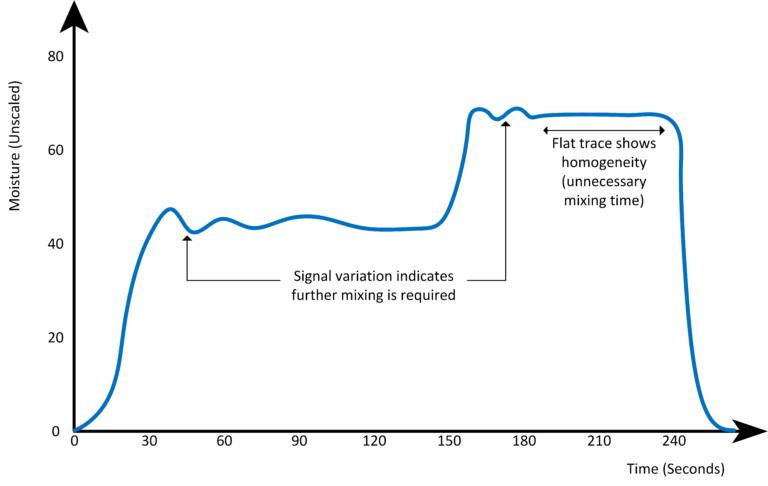

When the raw materials are loaded into the mixer, the sensor can record the moisture variation between the wet aggregates and the dry cementitious materials. As the materials mix with the dosed water and admixtures, the moisture signal changes as the material moves in the mixer.

As the water disperses evenly over the entire mix, the trace output from the mixer sensor flattens, indicating that homogeneity has been reached.

The use of homogeneity control allows the optimisation of mix cycles. Once the producer can evaluate whether the mix is homogenous or not, they can then adjust the mixing time to ensure that only the time required to homogenise the mix is used. Mixing for the right amount of time has considerable benefits in reduced power consumption, reduced wear of parts, and increased production output.

Moisture Measurement in Concrete Production is Cost-Efficient

As well as improvements in quality, the use of moisture control also allows improved profitability for a concrete production operation.

Concrete producers will reduce material costs and increase production yield. Although more difficult to quantify, the reduced number of sub-standard batches, reduced wear parts and energy savings contribute towards increased profitability. The improvement is such that over the past 30 years, many Hydronix customers have determined a return-on-investment period of between 3 to 6 months for the moisture control system.

If you are considering using moisture control equipment, first ensure that you choose a company with an excellent reputation. Second, the moisture control equipment needs to integrate with your current system. Finally, this company needs to have local partners who will give you the service and after-sales support you expect.